Phone

0(299) 123 452

0(299) 123 452

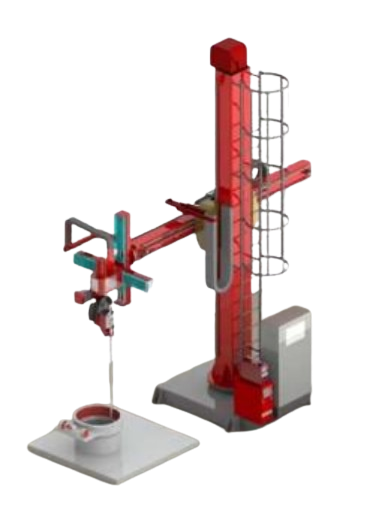

Device Name: ENDLESS TORCH ROTATION SYSTEM (ETR-S)

Welding Process: Hot-wire TIG;

Automatic programming ,Stable quality

Unlimited load, welding of oversized products;

AVC function, Stable and smooth welding

The ETR-S system is capable of welding large and heavy valves, as these valves do not require a turntable for rotation and can be placed directly on a flat surface (such as the ground or a fork platform)....

The ETR-S system has an automatic centering function, allowing the operator to simply move the welding gun to the required cladding hole before welding, and the system will automatically find the center and position itself.

The ETR-S system, in conjunction with specialized software, can achieve precise control over the intersecting line cladding of inner holes, avoiding errors that may arise from manual operation and improving welding quality and efficiency.

The ETR-S system combines the hot wire TIG surfacing process, featuring high deposition rate, low dilution rate, high welding speed, and large surfacing area, effectively improving welding efficiency, reducing operating costs, and meeting the demand for high-quality valve cladding.

Fornis Pipeline Company possesses 50 ETR-S units, with a welding capacity of 25 tons per month, operating efficiently and stably.

The ETR-S equipment welding capacity reaches 25 tons per month, demonstrating high efficiency and stability, and is adaptable to various product structural requirements.

Pipe

Pipe fittings

France

Pipe fittings

Valve body

Subsea oil tree body

Spray guard housing

If you have any questions, please contact us through messages.

No. 57 Runhuaidao, Lishui Economic Development Zone, Nanjing City

Telephone : 0(299) 123 452

mace@fnspipe.com